POLYMERIZATION

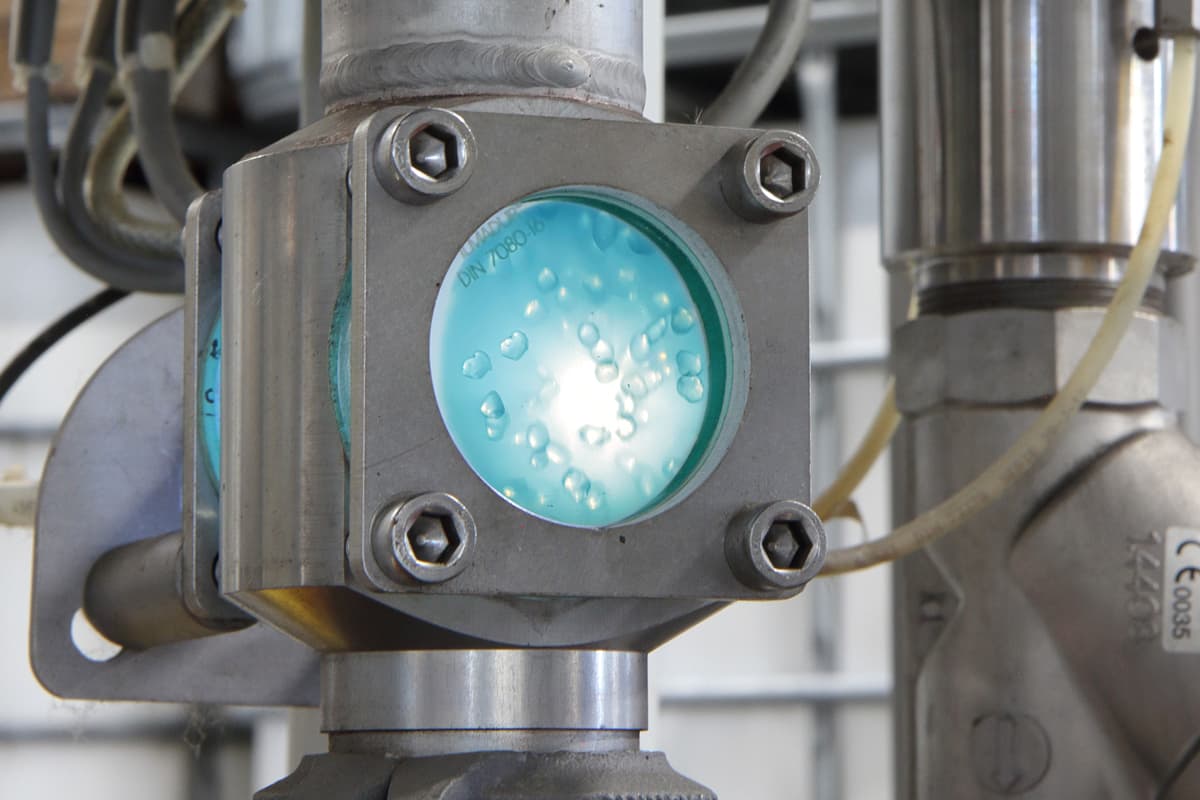

The first reactor for the polymerization of vinyl monomer acetate dates back to the 1980s: currently, the company has reactors with different flow rates for research & development in the field of new, increasingly high-performance polymers, suitable for meeting the requirements of new, advanced application technologies.

PRODUCTION OF COLD - WATER-BASED GLUES

The production of water-based glues is managed by a complex and multi-sided automation system that integrates and regulates not only the amount and proportioning of individual raw materials, through dedicated lines, but also the feeding and mixing time schedule: Giancol’s PLC programs the working sequence and optimises all the production phases for each batch and each production shift; the operators are only required to ensure quality control and careful monitoring of the filtration processes.

HOT MELT ADHESIVES

Since the end of the 1980s, the production of Hot Melt adhesives has been based on various automated technologies.

All the production phases, all the diathermic oil circuits and the cooling systems are also completely automated and managed by Giancol’s PLC.

PRESSURE SENSITIVE HOT MELT

NATURAL-BASED GLUES

Natural-based products (starches, caseins and dextrins) are made with hot and cold production technologies.

SOLVENT-BASED GLUES

A recent revamping of the production mixers for polychloroprene, polyurethane and thermoplastic adhesives has optimised the production phases carried out in controlled and nitrogen-regulated atmosphere.